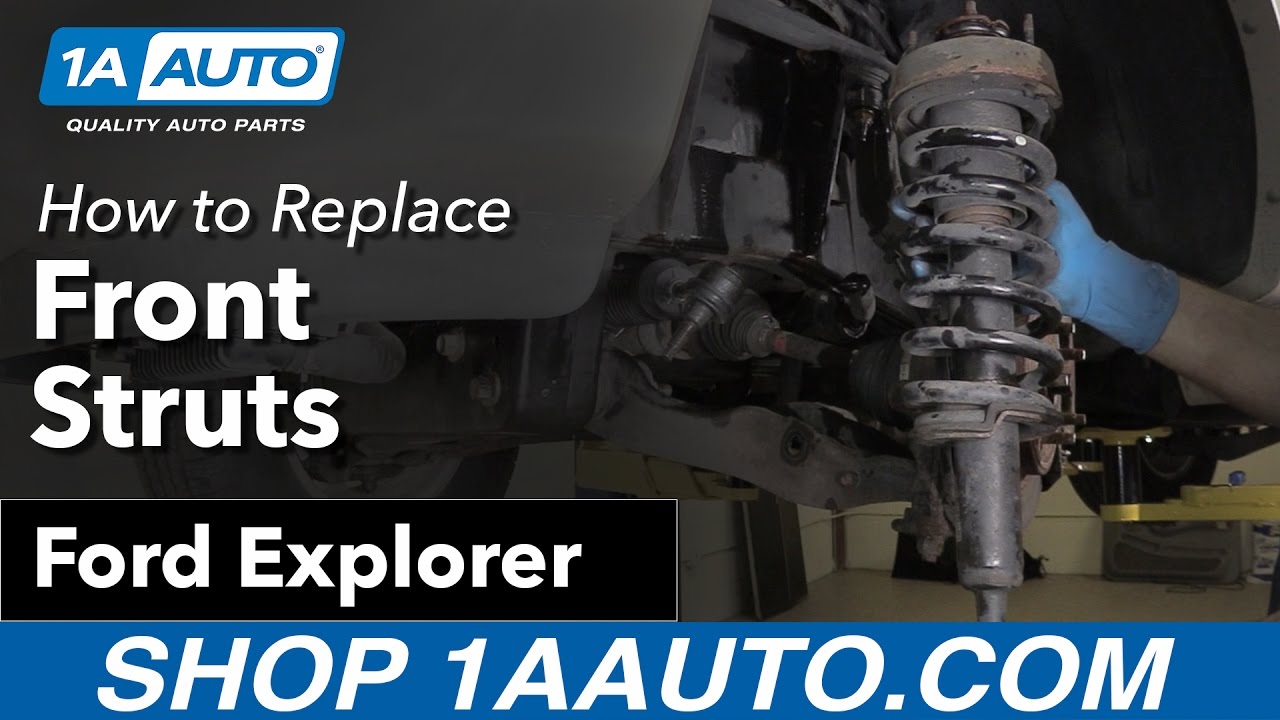

1ASTS00849-2006-10 Ford Explorer Mercury Mountaineer Front Strut & Spring Assembly TRQ SCA57563

Replaces

2010 Mercury Mountaineer Front Driver Side Strut & Spring Assembly TRQ SCA57563

Recommended for your 2010 Mercury Mountaineer

Product Reviews

Loading reviews

Customer Q&A

No questions have been asked about this item.

Mercury is a registered trademark of Ford Motor Company. 1A Auto is not affiliated with or sponsored by Mercury or Ford Motor Company.

See all trademarks.