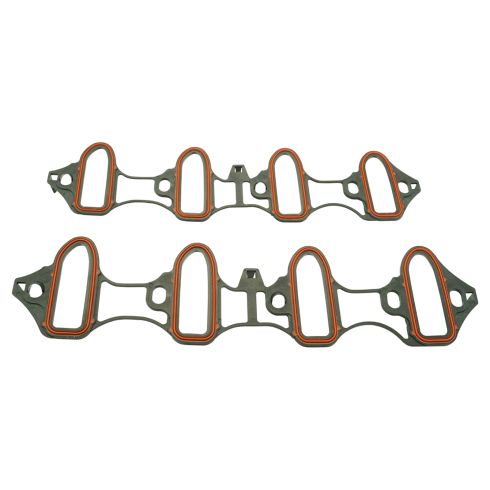

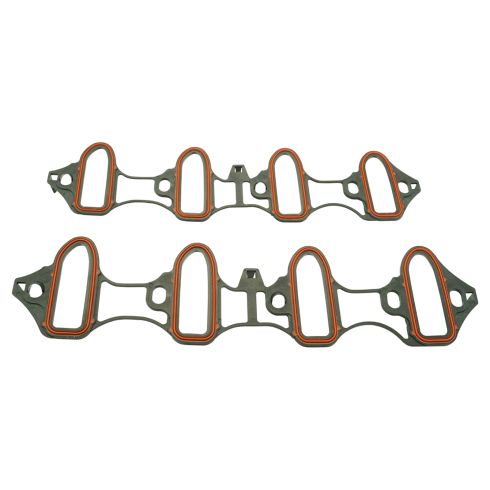

1AEGS00322-Intake Manifold Gasket Set TRQ SGA11383

Replaces

2004 Chevrolet Express 1500 Van V8 5.3L Intake Manifold Gasket Set TRQ SGA11383

Recommended for your 2004 Chevrolet Express 1500 Van

Frequently bought together

Product Reviews

Loading reviews

Customer Q&A

No questions have been asked about this item.

Chevrolet is a registered trademark of General Motors Company. 1A Auto is not affiliated with or sponsored by Chevrolet or General Motors Company.

See all trademarks.