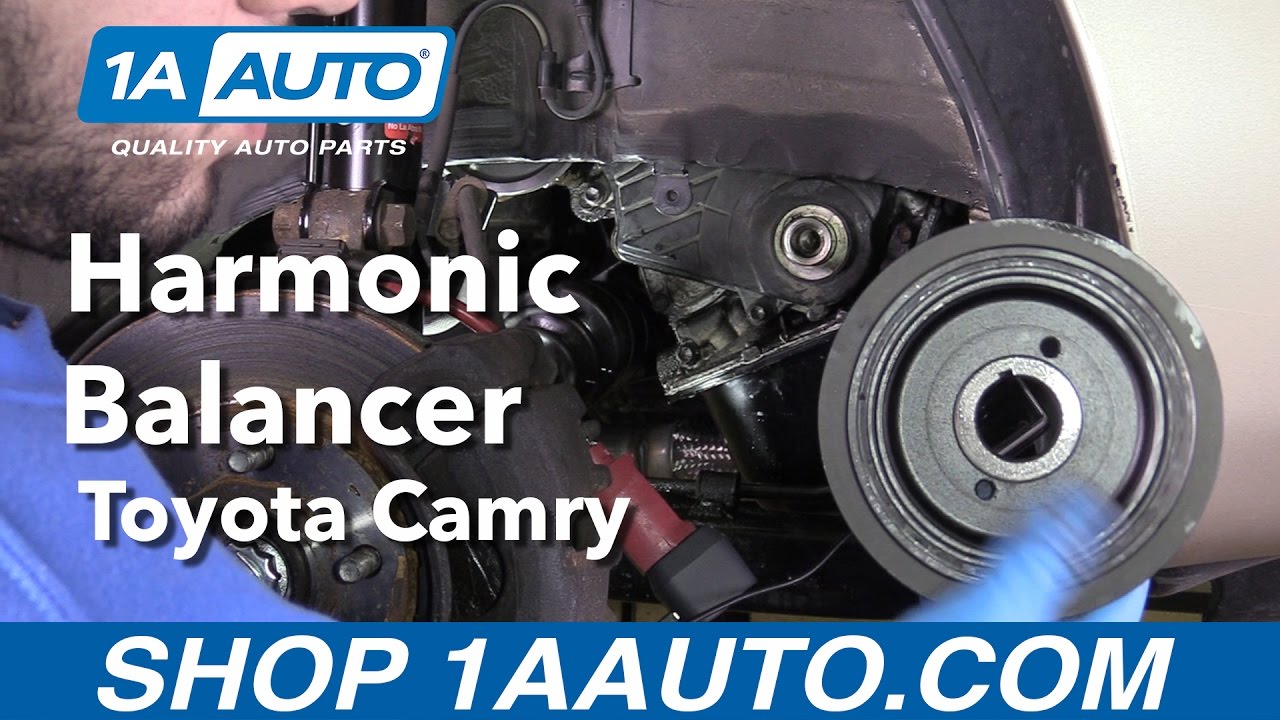

1AEHB00103-Toyota Camry Celica Rav4 Solara Engine Crankshaft Vibration Damper TRQ BPA06022

Replaces

1992 Toyota Camry L4 2.2L Engine Crankshaft Vibration Damper TRQ BPA06022

Recommended for your 1992 Toyota Camry

Product Reviews

Loading reviews

Customer Q&A

No questions have been asked about this item.

Toyota is a registered trademark of Toyota Motor Corporation. 1A Auto is not affiliated with or sponsored by Toyota or Toyota Motor Corporation.

See all trademarks.